Center Drive Lathe Machining is a revolutionary turning technique that allows both ends of a workpiece to be machined simultaneously in a single setup.

The development of this technology stems from the manufacturing industry’s constant demand for higher efficiency and precision. Traditional lathes required two steps (machining one end, then flipping the part to machine the other), but dual-end simultaneous machining evolved in the late 20th century as CNC control and machine design advanced.

In the early days, machinists often had to machine one end of a long shaft, then flip the workpiece to finish the other end – a cumbersome process that risked misalignment. To overcome this, special lathe concepts emerged around the mid-20th century, but the true breakthrough came with the maturation of center-drive lathe technology. With advances in CNC, these lathes allow both ends to be machined in one clamping, dramatically shortening the machining cycle while keeping the machining accuracy of both ends perfectly aligned. Compared to conventional lathes, dual-end simultaneous machining eliminates repetitive re-chucking and re-alignment steps, showing significant advantages in high-volume production settings.

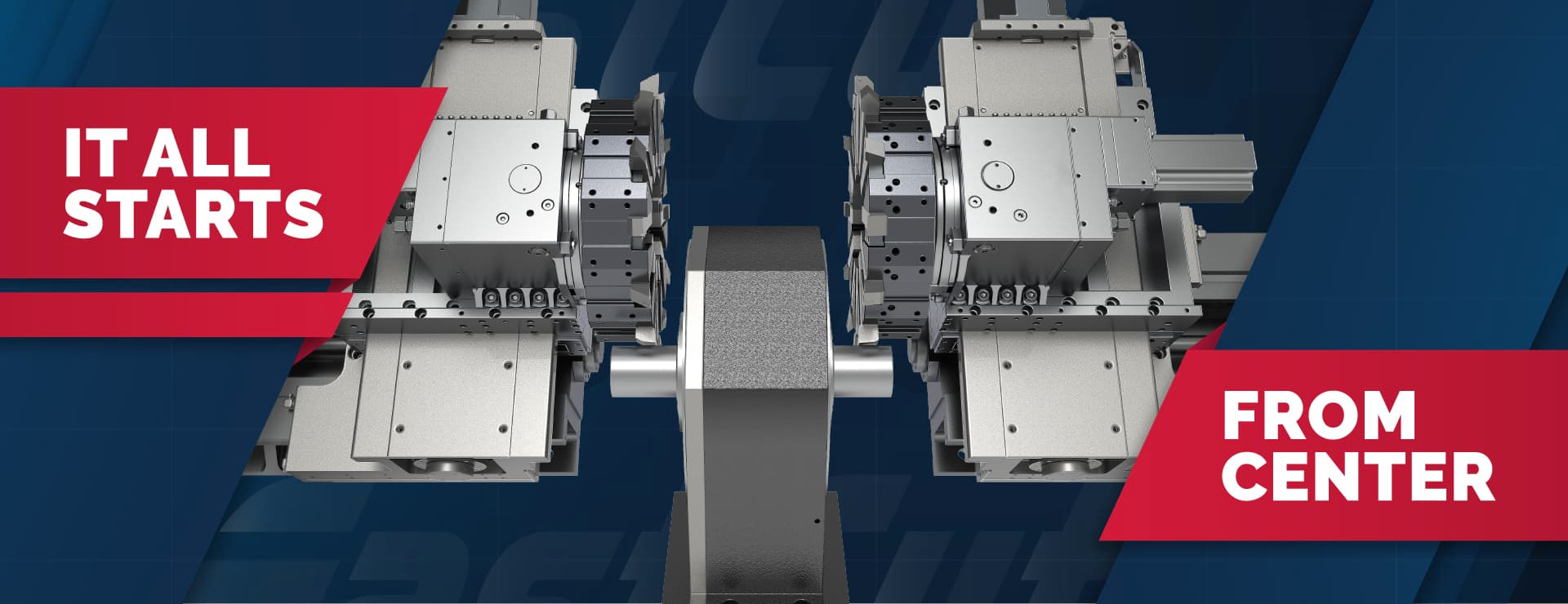

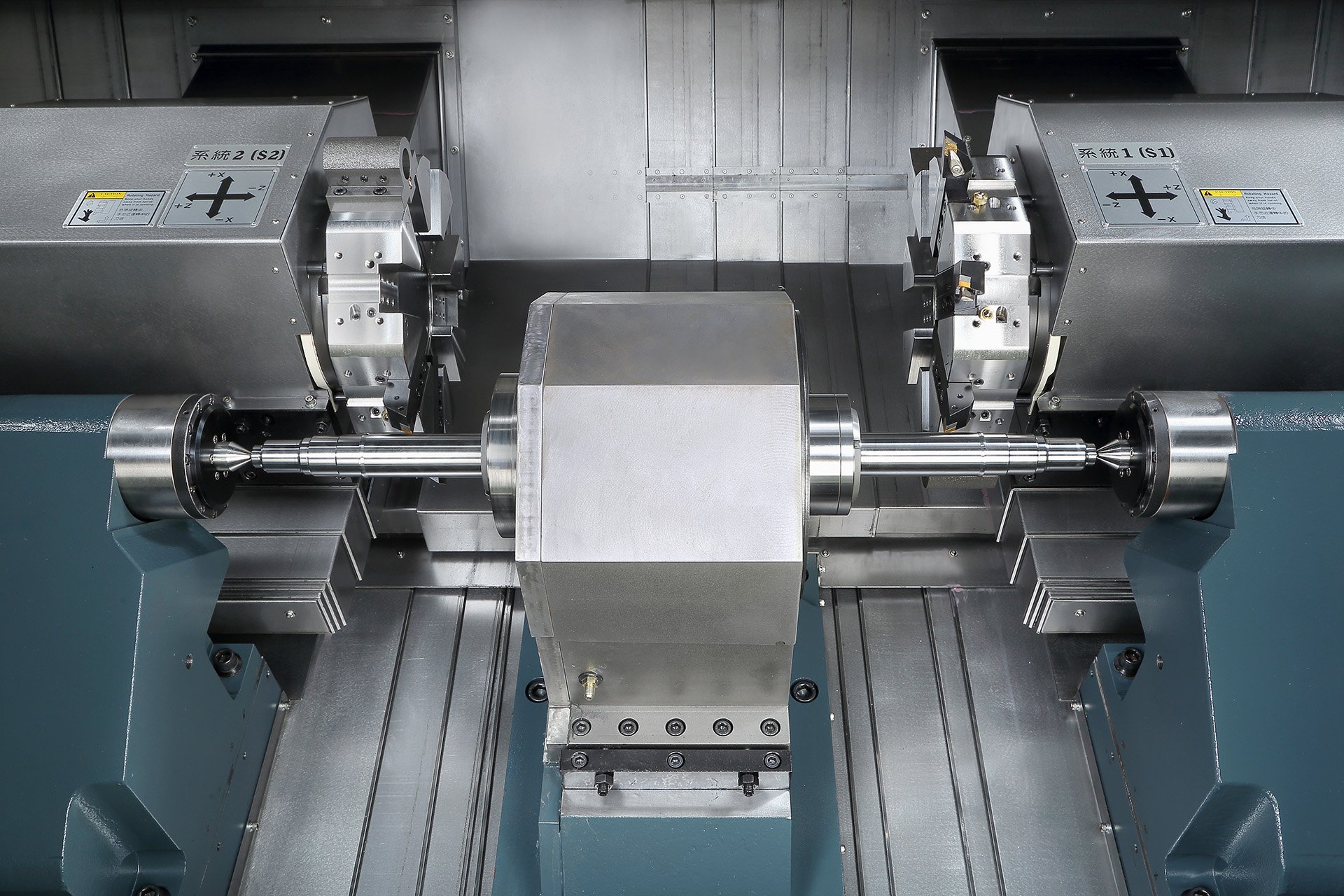

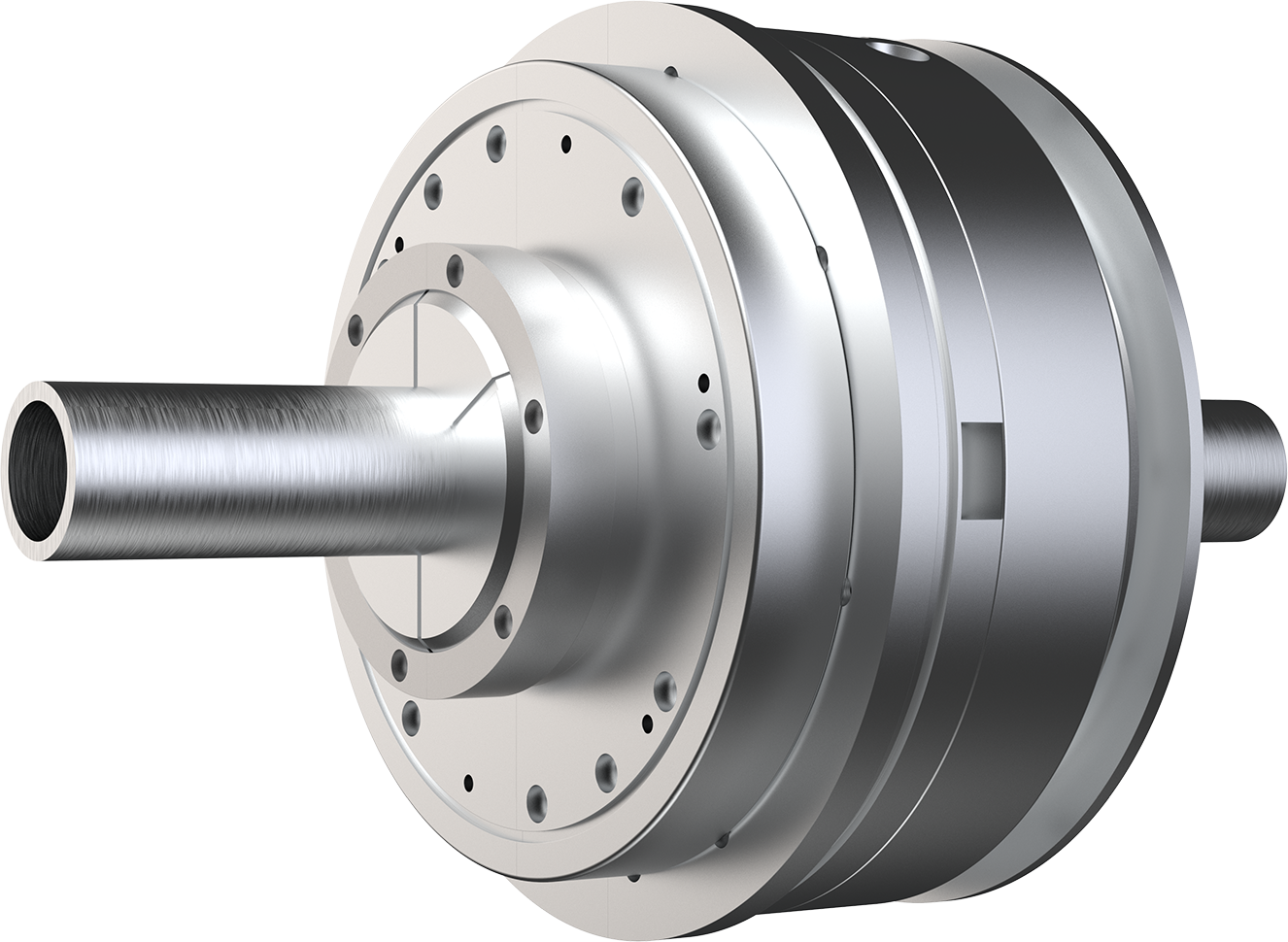

Inside a center drive lathe : The workpiece is clamped at its center by chucks from both sides, allowing simultaneous machining on both ends.

The lathe firmly holds the workpiece at its center using a hydraulic clamping system. This stable grip ensures the part remains aligned during high-speed, dual-end simultaneous machining. Once clamped, both turrets can operate at the same time, significantly reducing cycle time and improving concentricity. The entire machining process is completed in a single setup—no flipping required—boosting productivity and minimizing error risks.

After machining is complete, the chuck automatically releases the workpiece, allowing the process to move to the next stage. Since clamping and unclamping are fully automated, the transition is extremely fast—some models can complete reloading within just a few seconds. In automated production lines, robotic arms or feeders work in sync with the system to achieve continuous operation and quick part exchange. This fast and reliable cycle supports stable production flow and high output efficiency.

-

For example, when machining a drive shaft, the left turret turns and drills one end while the right turret threads or bores the opposite end. Throughout the process, the workpiece remains in the chuck, ensuring higher efficiency and precision while eliminating concentricity errors from flipping. This technique is ideal for long shafts and pipes, making machining faster, safer, and more efficient.

By clamping in the center and machining both ends simultaneously, dual-end machining significantly reduces production time while ensuring high precision.

Stay tuned for our next newsletter, where we’ll explore its three key advantages!

At Fastcut, we aim to provide professional yet approachable insights, helping you find the best solutions for your needs. Feel free to contact us anytime for further information!

Fastcut - It All Starts from Center